Optimal Material Gauges for Custom Cake Pan Manufacturing

In the realm of crafting custom cake pans, the choice of material gauge stands as a critical factor that significantly influences the quality, versatility, and production efficiency of these essential baking tools. At our esteemed manufacturing facility, we’ve meticulously developed a range of four custom cake pan gauges, each tailored to specific applications and baking needs. Let’s delve into these material gauges and their respective functionalities:

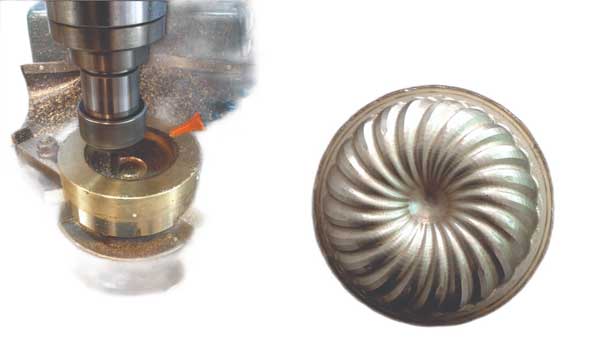

1. Gauge 24: Crafting Gelatin Molds with Precision

For the artistry of gelatin molds, we introduce Gauge 24, a material that embodies both flexibility and finesse. Our precision-engineered Gauge 24 aluminum, with a temper rating of “0,” exhibits exceptional malleability, making it ideal for creating elegantly rounded geometries. This gauge opens the doors to crafting a plethora of aluminum molds, tailored exclusively for gelatin creations. The innate pliability of Gauge 24 allows us to shape intricate designs that beautifully encapsulate your gelatin masterpieces. However, it’s important to note that while this gauge shines in gelatin mold creation, for production efficiency and cost-effectiveness, we recommend exploring the realm of plastic injection molding for large-scale gelatin mold production.

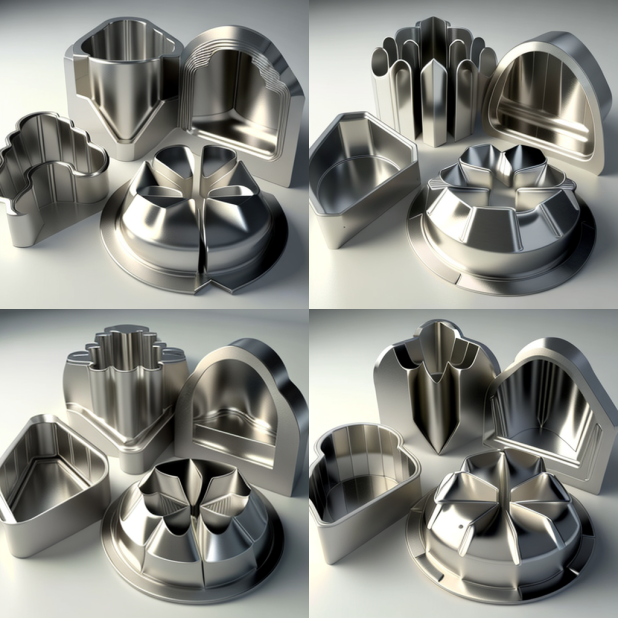

2. Gauge 22: The Home Enthusiast’s Perfect Pick

Stepping into the heart of home baking, we unveil Gauge 22 – a versatile champion for creating custom cake pans destined for domestic kitchens. This gauge bridges the gap between delicate artistry and practicality. With a seamless transition from the finesse of Gelatin Molds, Gauge 22 is robust and reliable, ideal for crafting cake pans that cater to home bakers seeking perfection in every bite.

3. Gauge 18: A Step Towards Industrial Craftsmanship

As we venture into more industrially-oriented applications, Gauge 18 emerges as the optimal choice. This gauge seamlessly balances durability and longevity, making it the ideal gauge for slightly more intensive usage. The thickness of Gauge 18 ensures resilience, allowing for frequent use without compromising on the structural integrity of the cake pans. From small-scale baking endeavors to catering services, this gauge takes the art of cake pan creation to the next level.

4. Gauge 16: Industrial Power and Precision

Finally, as we embrace a more robust industrial application spectrum, we present Gauge 16. This gauge is tailored for high-volume production environments where consistency, durability, and efficiency are paramount. With its substantial thickness, Gauge 16 offers the strength needed to withstand the rigors of continuous use in commercial bakeries, confectioneries, and catering services.

In essence, our meticulous selection of custom cake pan gauges is a testament to our commitment to delivering baking solutions tailored to your needs. From the delicacy of gelatin molds to the resilience of industrial-grade applications, each gauge reflects our dedication to precision engineering and versatile functionality. As you embark on your baking journey, consider these gauges as your ally in creating culinary masterpieces that resonate with your vision and exceed your expectations.

In the world of baking, precision and quality are key, and the choice of the right custom cake pan gauge can make all the difference. Our range of meticulously designed gauges, from Gauge 24 to Gauge 16, embodies the essence of versatility, durability, and artistry. Whether you’re delving into the delicate art of gelatin molds, baking for your home kitchen, or catering to the demands of commercial baking, our custom cake pan gauges are crafted to meet your unique needs.

Gauge 24 showcases the beauty of malleability, breathing life into intricate gelatin molds with ease. As we step into domestic kitchens, Gauge 22 takes the center stage, combining finesse with practicality for the passionate home bakers. Gauge 18 marks a transition towards more intensive use, catering to both craftsmanship and longevity. And for the demands of high-volume production, Gauge 16 emerges as the powerhouse, ensuring consistency and durability on an industrial scale.

In every gauge, we channel our commitment to precision engineering, ensuring that each cake pan created is a testament to our dedication to baking perfection. As you embark on your culinary endeavors, let our custom cake pan gauges be your trusted partners, enabling you to create confections that not only taste exquisite but also reflect the artistry and craftsmanship that define your baking journey.